Understanding the Working Principle of Industrial Dust Collector Systems

Vues : 0

Auteur : Rédacteur du site

Heure de publication : 2026-01-27

Origine : Site

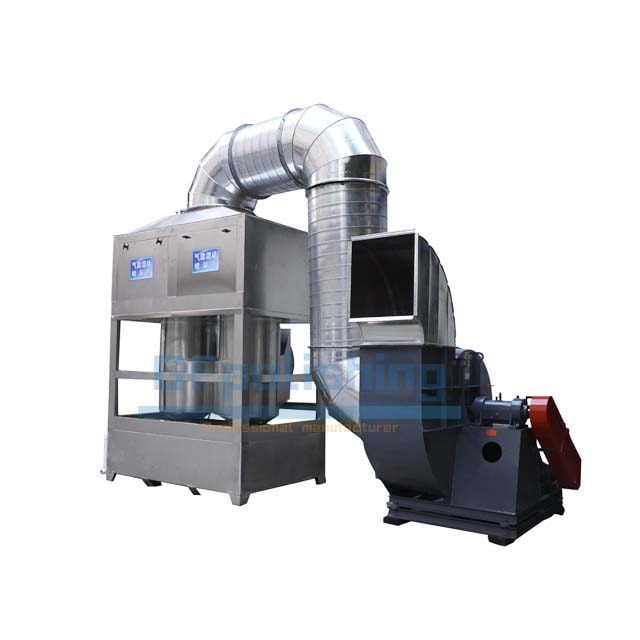

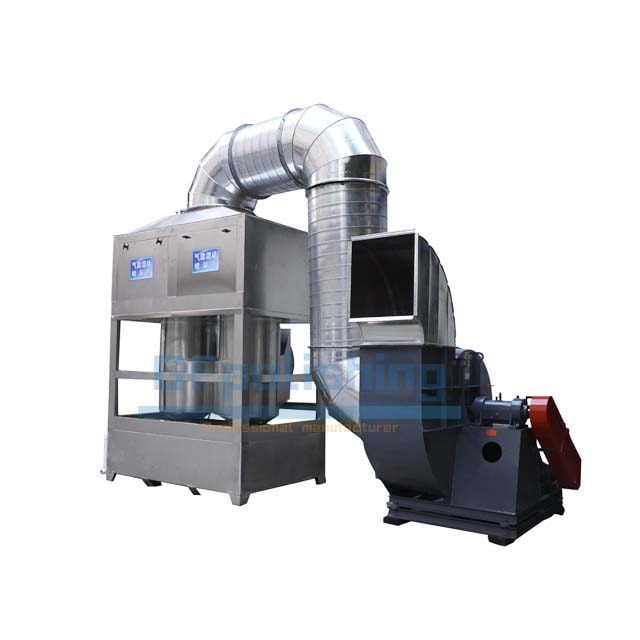

Industrial dust collector systems play a critical role in modern manufacturing environments by controlling airborne contaminants and ensuring a safe, clean workplace. As factories and production lines become more automated and efficient, the need for advanced dust collection solutions has never been greater. Dongguan Guangfan Automation Technology Co., LTD, known in the industry as Guangfan Automation, stands at the forefront of this technological evolution, offering state-of-the-art industrial dust collector systems that cater to diverse industry needs.

Latest Developments in Industrial Dust Collection

In recent news, the demand for efficient and reliable industrial dust collector systems has surged, especially as environmental regulations tighten and workplace safety standards rise globally. Guangfan Automation has responded by integrating innovative features into their dust collector systems, such as automated filter cleaning and real-time air quality monitoring. These advancements have set new benchmarks for operational efficiency and environmental compliance across multiple sectors.

Dépoussiéreur de type humide en acier inoxydable pour le dépoussiérage

cyclone tower water type dust collector for polishing machine

industrial indoor wet dust collector for grinding machine

wet dust collector for polishing buffing machine

Guangfan Automation’s latest series of dust collectors are designed not only to capture fine particulate matter but also to adapt to variable production loads, making them suitable for industries ranging from electronics and pharmaceuticals to woodworking and metal fabrication. Their commitment to research and development ensures that their systems remain at the cutting edge of industry trends.

Working Principle of Industrial Dust Collector Systems

At the core of every industrial dust collector system is a simple yet effective principle: removing particulate contaminants from the air to maintain a safe and clean working environment. The process typically begins with the collection of dust-laden air through a network of ducts or hoods strategically placed at dust generation points. The air is then drawn into the dust collector unit, where it undergoes several stages of filtration.

- Pre-Filtration: Larger particles are separated from the airstream using cyclonic action or gravity-based separators.

- Main Filtration: Fine dust is captured by high-efficiency filter media, such as fabric bags, cartridge filters, or HEPA filters.

- Filter Cleaning: Advanced systems, like those from Guangfan Automation, employ pulse-jet cleaning or mechanical shaking to dislodge accumulated dust, ensuring consistent airflow and prolonged filter life.

- Clean Air Discharge: The filtered, clean air is either recirculated back into the workspace or safely vented outdoors, depending on the application and regulatory requirements.

The integration of automated controls and monitoring sensors allows for real-time adjustments, enhancing both energy efficiency and dust collection performance. Guangfan Automation’s systems are engineered to minimize downtime and maintenance, further optimizing operational productivity.

Industry Applications and the Role of Industrial Fans

Industrial dust collector systems are indispensable in sectors where airborne particulates pose health hazards or threaten product quality. For instance, in the electronics manufacturing industry, even microscopic dust can compromise the integrity of sensitive components. Similarly, in woodworking and metalworking, dust accumulation can increase the risk of fire and equipment malfunction.

A key component that enhances the performance of dust collection systems is the industrial fan. Industrial fans generate the necessary airflow to transport dust-laden air from the source to the filtration unit. Guangfan Automation meticulously designs and selects industrial fans to ensure optimal airflow rates, energy efficiency, and quiet operation, tailored to the specific requirements of each application.

Moreover, the company’s expertise extends to the development of specialized centrifugal fans, which are particularly effective in handling high volumes of air and maintaining stable pressure levels across complex ductwork systems. These centrifugal fans are engineered for durability and consistent performance, even in demanding industrial environments.

Advantages of Guangfan Automation’s Dust Collector Systems

- High-Efficiency Filtration: Multi-stage filtration ensures the removal of both coarse and fine particulates.

- Automated Maintenance: Self-cleaning filters reduce manual intervention and prolong system lifespan.

- Real-Time Monitoring: Integrated sensors provide instant feedback on system performance and air quality.

- Customizable Solutions: Systems can be tailored to specific industry requirements and facility layouts.

- Energy Savings: Advanced fan technology and intelligent controls minimize power consumption.

Tendances de l'industrie et perspectives d'avenir

The industrial dust collector market is evolving rapidly, driven by stricter environmental regulations, growing awareness of occupational health, and the push for sustainable manufacturing practices. Companies like Guangfan Automation are investing heavily in research and development to stay ahead of these trends. The integration of IoT technology and smart sensors is enabling predictive maintenance, remote monitoring, and data-driven optimization of dust collection systems.

Additionally, the adoption of energy-efficient industrial fans and centrifugal fans is helping manufacturers reduce their carbon footprint while maintaining high standards of air quality. The use of advanced materials in filter construction is also extending filter life and reducing waste, contributing to the circular economy.

Looking forward, the role of automation and digitalization in dust collection is expected to expand. Intelligent systems that can self-adjust based on real-time data will become the norm, further enhancing workplace safety and environmental compliance.

Conclusion

Dongguan Guangfan Automation Technology Co., LTD (Guangfan Automation) continues to set industry standards with its innovative industrial dust collector systems. By combining advanced filtration technology, smart automation, and robust industrial and centrifugal fans, the company delivers comprehensive solutions that address the evolving needs of modern manufacturing. As the industry moves towards greater efficiency and sustainability, Guangfan Automation remains a trusted partner for businesses seeking to create cleaner, safer, and more productive work environments.