Η λείανση σωλήνων εξυπηρετεί διάφορους σκοπούς:

1. Φινίρισμα επιφάνειας: Παρέχει γυαλισμένο φινίρισμα για να διασφαλιστεί ότι οι σωλήνες πληρούν τις αισθητικές ή υγειονομικές απαιτήσεις, ιδίως σε βιομηχανίες όπως τα τρόφιμα και τα ποτά, τα φαρμακευτικά προϊόντα και οι κατασκευές.

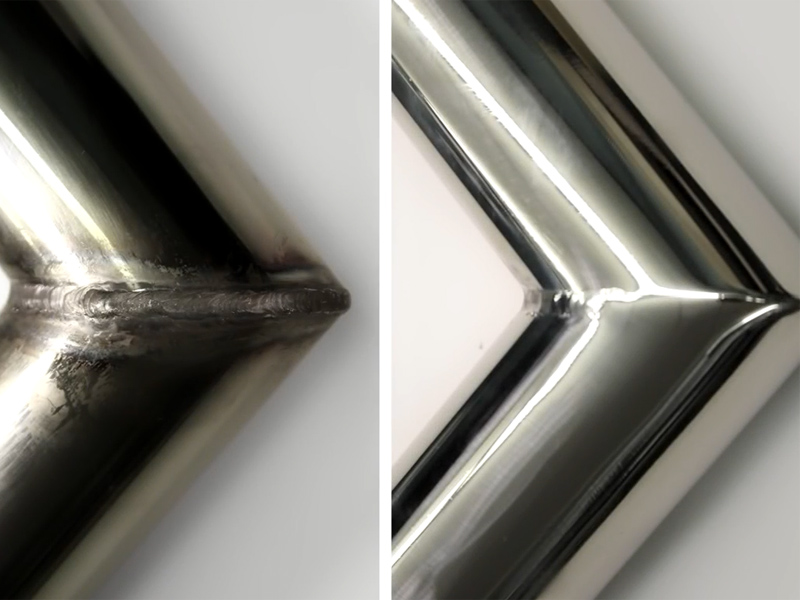

2. Προετοιμασία για επικάλυψη ή συγκόλληση: Η λείανση μπορεί να είναι απαραίτητη για την προετοιμασία των επιφανειών για επιστρώσεις ή συγκολλήσεις, βελτιώνοντας την πρόσφυση και εξασφαλίζοντας μια καθαρότερη ένωση.

3. Ξεκαθάρισμα: Η διαδικασία βοηθά στην εξάλειψη των αιχμηρών άκρων και των γρεζιών που έχουν απομείνει από τις εργασίες κοπής ή κατεργασίας, καθιστώντας τους σωλήνες ασφαλέστερους στο χειρισμό και μειώνοντας τον κίνδυνο τραυματισμού.

4. Διαμόρφωση περιγράμματος και διαστασιολόγηση: Σε ορισμένες εφαρμογές, η λείανση σωλήνων μπορεί να χρησιμοποιηθεί για την επίτευξη ακριβών μετρήσεων ή για τη δημιουργία συγκεκριμένων περιγραμμάτων.

Οι μηχανές λείανσης ταξινομούνται συνήθως σε διάφορους τύπους με βάση τις ειδικές εφαρμογές και διαμορφώσεις τους. Οι τρεις κύριοι τύποι μηχανών λείανσης είναι οι εξής:

Μια μηχανή λείανσης σωλήνων, που ονομάζεται επίσης μηχανή λείανσης σωλήνων, είναι ένας εξειδικευμένος τύπος εξοπλισμού λείανσης που έχει σχεδιαστεί ειδικά για τη λείανση μεταλλικών σωλήνων και σωληνώσεων. Αυτά τα μηχανήματα χρησιμοποιούνται κυρίως σε βιομηχανίες όπου απαιτείται η κατασκευή ή η συντήρηση σωληνώσεων, όπως οι υδραυλικές εγκαταστάσεις, η HVAC και η μεταποίηση.

Ο πρωταρχικός στόχος μιας μηχανής λείανσης σωλήνων είναι η εξομάλυνση και το φινίρισμα των επιφανειών των σωλήνων, η αφαίρεση των ραφών συγκόλλησης και η προετοιμασία των σωλήνων για περαιτέρω επεξεργασία, όπως η επίστρωση ή η κάμψη.

Ένας μύλος σωλήνων έχει σχεδιαστεί για να επεξεργάζεται αποτελεσματικά μια ποικιλία μεταλλικών υλικών, όπως: Ανοξείδωτο χάλυβα, ανθρακούχο χάλυβα, αλουμίνιο, χαλκό, ορείχαλκο.

Η τιμή των μηχανημάτων λείανσης μεταλλικών σωλήνων μπορεί να διαφέρει σημαντικά ανάλογα με παράγοντες όπως οι δυνατότητες, το μέγεθος και ο κατασκευαστής του μηχανήματος. Κατά μέσο όρο, μπορείτε να περιμένετε να πληρώσετε από $5.000 έως πάνω από $20.000 για μια μηχανή λείανσης σωλήνων υψηλής ποιότητας σχεδιασμένη για επεξεργασία μετάλλων. Καλώς ήρθατε στην επικοινωνήστε μαζί μας για ανταγωνιστική τιμή.

Κατά την επιλογή μιας μηχανής λείανσης σωλήνων, οι δυνητικοί αγοραστές πρέπει να εξετάσουν διάφορα βασικά χαρακτηριστικά για να διασφαλίσουν ότι ο εξοπλισμός ανταποκρίνεται στις συγκεκριμένες ανάγκες παραγωγής τους. Ακολουθούν ορισμένα βασικά χαρακτηριστικά, συμπεριλαμβανομένων των απαιτήσεων ισχύος, της ταχύτητας, του μεγέθους των τροχών και της συμβατότητας των υλικών, τα οποία επηρεάζουν άμεσα την απόδοση και την εφαρμοσιμότητα του μηχανήματος.

1. Απαιτήσεις ισχύος

Η ισχύς είναι μία από τις κρίσιμες παραμέτρους μιας μηχανής λείανσης σωλήνων. Διαφορετικές μηχανές ισχύος έχουν σχεδιαστεί για διαφορετικούς τύπους εργασιών. Γενικά, τα μηχανήματα με μεγαλύτερη ισχύ μπορούν να χειριστούν παχύτερα και σκληρότερα υλικά, καθιστώντας ζωτικής σημασίας την επιλογή ενός μηχανήματος που ανταποκρίνεται στις απαιτήσεις ισχύος σας για να διασφαλιστεί η αποτελεσματικότητα και η ποιότητα της λείανσης. Εάν εργάζεστε κυρίως με μεγαλύτερους ή παχύτερους σωλήνες, η επιλογή ενός μηχανήματος με μεγαλύτερη ισχύ θα είναι πιο κατάλληλη. Αντίθετα, εάν ο φόρτος εργασίας είναι ελαφρύτερος, μπορεί να αρκεί ένα μηχάνημα με χαμηλότερη ισχύ.

2. Ταχύτητα

Η ταχύτητα είναι ένας άλλος κρίσιμος παράγοντας που επηρεάζει την αποτελεσματικότητα της λείανσης και το τελικό φινίρισμα της επιφάνειας. Διαφορετικά υλικά και μεγέθη σωλήνων απαιτούν διαφορετικές ταχύτητες για βέλτιστα αποτελέσματα. Συνήθως, οι υψηλότερες ταχύτητες μπορούν να αλέσουν τα υλικά πιο γρήγορα, αλλά μπορεί επίσης να οδηγήσουν σε υπερθέρμανση και ζημιά στο τεμάχιο. Επομένως, η κατανόηση της απαιτούμενης ταχύτητας λείανσης και η επιλογή μιας μηχανής που να ανταποκρίνεται στα συγκεκριμένα υλικά και εφαρμογές με τις οποίες εργάζεστε είναι απαραίτητη.

3. Μέγεθος τροχού

Το μέγεθος του τροχού λείανσης επηρεάζει άμεσα το βάθος λείανσης και τη συνολική απόδοση. Οι μεγαλύτεροι τροχοί μπορούν να καλύψουν μεγαλύτερη επιφάνεια, βελτιώνοντας έτσι την αποτελεσματικότητα της λείανσης, αλλά οι μικρότεροι τροχοί μπορεί να είναι πιο ευέλικτοι κατά το χειρισμό μικρών ή πολύπλοκου σχήματος σωλήνων. Είναι σημαντικό να επιλέξετε το κατάλληλο μέγεθος τροχού με βάση τις απαιτήσεις εργασίας σας και τα σχήματα, τις διαμέτρους και τις ανάγκες λείανσης των σωλήνων που θα επεξεργαστείτε.

4. Συμβατότητα υλικών

Η συμβατότητα υλικών είναι ένα ζωτικής σημασίας χαρακτηριστικό που πρέπει να εξετάσουν οι δυνητικοί αγοραστές όταν επιλέγουν μια μηχανή λείανσης σωλήνων. Διαφορετικές εργασίες λείανσης περιλαμβάνουν διάφορα υλικά σωλήνων, όπως ανοξείδωτο χάλυβα, αλουμίνιο και ανθρακούχο χάλυβα. Η διασφάλιση ότι η μηχανή λείανσης σωλήνων που αγοράζετε μπορεί να λειτουργήσει με τα υλικά που πρέπει να επεξεργαστείτε είναι ζωτικής σημασίας. Κάθε υλικό παρουσιάζει διαφορετικά χαρακτηριστικά κοπής και ρυθμούς φθοράς κατά τη διάρκεια της λείανσης, οπότε η επιλογή ενός μηχανήματος που προσφέρει καλή συμβατότητα υλικών θα ενισχύσει την αποτελεσματικότητα της ροής εργασίας σας και θα διατηρήσει τα απαιτούμενα πρότυπα ποιότητας.

Η συντήρηση της μηχανής λείανσης σωλήνων είναι απαραίτητη για τη διασφάλιση της μακροζωίας και της βέλτιστης απόδοσής της. Ακολουθώντας τις βέλτιστες πρακτικές για τη συντήρηση, μπορείτε να ενισχύσετε την αποδοτικότητα και να αποφύγετε δαπανηρές επισκευές. Ακολουθούν ορισμένες βασικές συμβουλές για να διατηρήσετε το μηχάνημα λείανσης σωλήνων σας σε άριστη κατάσταση.

1. Τακτικός καθαρισμός

Η διατήρηση του μηχανήματός σας καθαρού είναι θεμελιώδης για την απόδοσή του. Μετά από κάθε χρήση, απομακρύνετε τη σκόνη, τα συντρίμμια και τα μεταλλικά ροκανίδια από τις επιφάνειες του μηχανήματος. Δώστε ιδιαίτερη προσοχή στην περιοχή λείανσης, καθώς τα συσσωρευμένα σωματίδια μπορεί να επηρεάσουν την ποιότητα της εργασίας σας και την απόδοση του μηχανήματος. Ένα καθαρό περιβάλλον συμβάλλει επίσης στην πρόληψη της σκουριάς και της διάβρωσης.

2. Αντικατάσταση τροχού

Ο τροχός λείανσης είναι ένα κρίσιμο εξάρτημα που φθείρεται με την πάροδο του χρόνου. Ελέγχετε τακτικά τον τροχό για σημάδια βλάβης, όπως ρωγμές ή υπερβολική φθορά. Εάν ο τροχός έχει φθαρεί, αντικαταστήστε τον αμέσως για να εξασφαλίσετε αποτελεσματική λείανση και να αποφύγετε πιθανούς κινδύνους για την ασφάλεια. Βεβαιωθείτε ότι έχετε επιλέξει το σωστό μέγεθος και τύπο τροχού που είναι συμβατός με τα υλικά που επεξεργάζεστε.

3. Πρακτικές λίπανσης

Η σωστή λίπανση είναι ζωτικής σημασίας για τη διατήρηση της ομαλής λειτουργίας των κινούμενων μερών της μηχανής λείανσης σωλήνων. Ελέγχετε τακτικά τα επίπεδα λιπαντικού και βεβαιωθείτε ότι τα γρανάζια, τα ρουλεμάν και άλλα σημεία τριβής λιπαίνονται επαρκώς. Η τήρηση των οδηγιών του κατασκευαστή σχετικά με τον τύπο και τη συχνότητα λίπανσης μπορεί να παρατείνει σημαντικά τη διάρκεια ζωής του μηχανήματος και να βελτιώσει την απόδοσή του.

4. Παρακολούθηση επιδόσεων

Ελέγχετε τακτικά την απόδοση της μηχανής λείανσης. Δώστε προσοχή σε τυχόν ασυνήθιστους θορύβους, δονήσεις ή αλλαγές στην ποιότητα λείανσης, καθώς αυτά μπορεί να υποδεικνύουν προβλήματα συντήρησης. Η έγκαιρη αντιμετώπιση των προβλημάτων μπορεί να συμβάλει στην αποφυγή πιο σημαντικών ζημιών και χρόνου διακοπής λειτουργίας. Η τήρηση αρχείου καταγραφής των επιδόσεων μπορεί επίσης να βοηθήσει στην παρακολούθηση τυχόν επαναλαμβανόμενων προβλημάτων.

5. Επαγγελματική εξυπηρέτηση

Ενώ η συνήθης συντήρηση μπορεί να γίνει στο σπίτι, συνιστάται ο προγραμματισμός περιοδικής επαγγελματικής συντήρησης. Οι έμπειροι τεχνικοί μπορούν να διεξάγουν ενδελεχείς επιθεωρήσεις και επισκευές, αντιμετωπίζοντας πολύπλοκα ζητήματα που ενδέχεται να προκύψουν. Η τακτική επαγγελματική συντήρηση όχι μόνο παρατείνει τη διάρκεια ζωής του εξοπλισμού σας, αλλά και εξασφαλίζει ότι λειτουργεί με μέγιστη απόδοση.

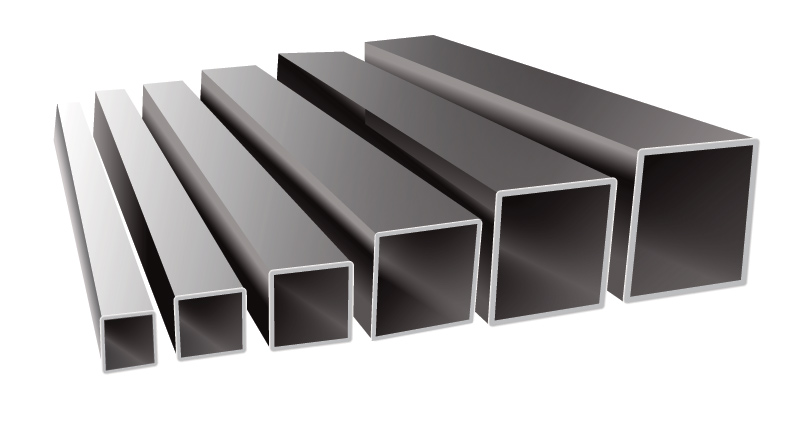

Η στίλβωση τετράγωνων σωλήνων με τη χρήση μηχανής λείανσης και στίλβωσης τετράγωνων σωλήνων είναι μια αποτελεσματική μέθοδος. Ακολουθεί ένας οδηγός βήμα προς βήμα για το πώς να το κάνετε:

1. Μηχανή λείανσης και στίλβωσης τετράγωνου σωλήνα: Ειδικά σχεδιασμένο για λείανση και στίλβωση τετράγωνων και ορθογώνιων σωλήνων.

2. Ζώνες λείανσης/Δίσκοι στίλβωσης: Επιλέξτε τον κατάλληλο κόκκο (π.χ. από χοντρό σε λεπτό).

3. Εξοπλισμός ασφαλείας: Γάντια, γυαλιά και μάσκα σκόνης.

4. Είδη καθαρισμού: Απολιπαντικό και πανιά για τον καθαρισμό.

1. Προετοιμασία:

- Φορέστε εξοπλισμό ασφαλείας, συμπεριλαμβανομένων γαντιών και γυαλιών, για να διασφαλίσετε την ασφάλεια κατά τη διάρκεια της διαδικασίας.

- Βεβαιωθείτε ότι ο χώρος εργασίας είναι καθαρός και οργανωμένος για να αποφύγετε τη μόλυνση.

2. Καθαρίστε τους σωλήνες:

- Καθαρίστε σχολαστικά τον τετράγωνο σωλήνα χρησιμοποιώντας ένα απολιπαντικό και ένα πανί για να αφαιρέσετε το λίπος, τη βρωμιά και την οξείδωση.

- Βεβαιωθείτε ότι ο σωλήνας είναι εντελώς στεγνός πριν προχωρήσετε.

3. Επιλέξτε ιμάντες/δίσκοι λείανσης/γυαλίσματος:

- Επιλέξτε τον κατάλληλο κόκκο για τους ιμάντες λείανσης ή τους δίσκους στίλβωσης ανάλογα με την κατάσταση της επιφάνειας. Για τραχιές επιφάνειες, ξεκινήστε με χοντρό κόκκο- για πιο λεπτές επιφάνειες, χρησιμοποιήστε λεπτότερο κόκκο.

4. Ρύθμιση του μηχανήματος:

- Ρυθμίστε την ταχύτητα και την πίεση της μηχανής λείανσης και στίλβωσης ανάλογα με τα χαρακτηριστικά του υλικού για να αποφύγετε την καταστροφή των σωλήνων.

5. Ξεκινήστε το γυάλισμα:

- Τοποθετήστε τον τετράγωνο σωλήνα με ασφάλεια στη μηχανή λείανσης.

- Εκκινήστε τη μηχανή και μετακινήστε αργά το σωλήνα προς τον ιμάντα ή το δίσκο λείανσης. Βεβαιωθείτε για ομοιόμορφη πίεση και συνεπή κίνηση για να επιτύχετε ομοιόμορφη στίλβωση. Αποφύγετε να μένετε σε ένα σημείο για πολύ ώρα για να αποφύγετε την υπερθέρμανση.

6. Ελέγξτε τα αποτελέσματα:

- Μετά την αρχική στίλβωση, επιθεωρήστε την επιφάνεια του τετράγωνου σωλήνα. Μπορείτε να ψηλαφήσετε την επιφάνεια για την ομαλότητα και να παρατηρήσετε τη λάμψη.

7. Επαναλάβετε ανάλογα με τις ανάγκες:

- Εάν επιθυμείτε υψηλότερα επίπεδα στιλπνότητας, αντικαταστήστε τον ιμάντα ή τον δίσκο λείανσης με λεπτότερο κόκκο και επαναλάβετε τη διαδικασία στίλβωσης.

8. Τελικός καθαρισμός:

- Μόλις ολοκληρωθεί η στίλβωση, χρησιμοποιήστε ένα καθαρό πανί για να σκουπίσετε τον τετράγωνο σωλήνα για να απομακρύνετε τυχόν υπολείμματα λείανσης και σκόνη.

Πρόσθετες συμβουλές

- Εξαερισμός: Εξασφαλίστε ότι το περιβάλλον εργασίας αερίζεται καλά για να αποφύγετε επιβλαβείς αναθυμιάσεις.

- Τακτική συντήρηση: Ελέγχετε τακτικά την κατάσταση της μηχανής λείανσης και αντικαθιστάτε τους φθαρμένους ιμάντες ή δίσκους ανάλογα με τις ανάγκες.

- Ακολουθήστε τις οδηγίες του κατασκευαστή: Βασιστείτε στα εγχειρίδια λειτουργίας του μηχανήματος και των προϊόντων για να επιτύχετε τα καλύτερα αποτελέσματα.

Ακολουθώντας αυτά τα βήματα, μπορείτε να γυαλίσετε αποτελεσματικά τους τετράγωνους σωλήνες χρησιμοποιώντας μια μηχανή λείανσης και στίλβωσης τετράγωνων σωλήνων, επιτυγχάνοντας ένα επιθυμητό γυαλιστερό φινίρισμα.

Συνεχίζοντας να χρησιμοποιείτε τον ιστότοπο, συμφωνείτε με την πολιτική απορρήτου Όροι και Προϋποθέσεις.