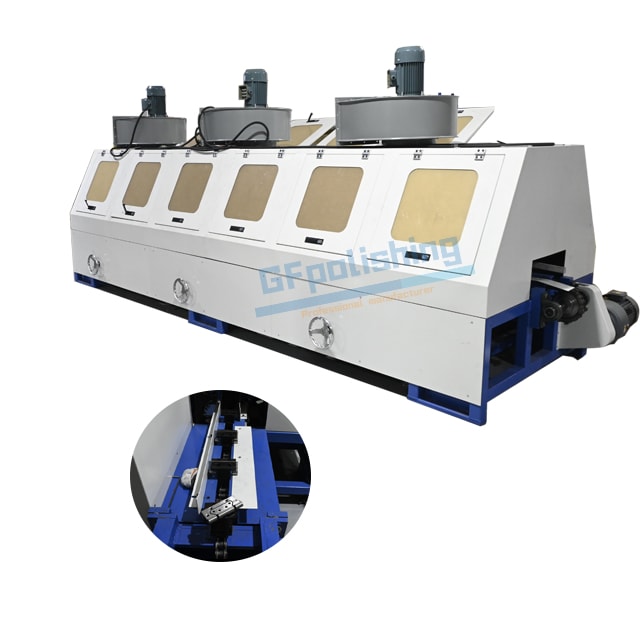

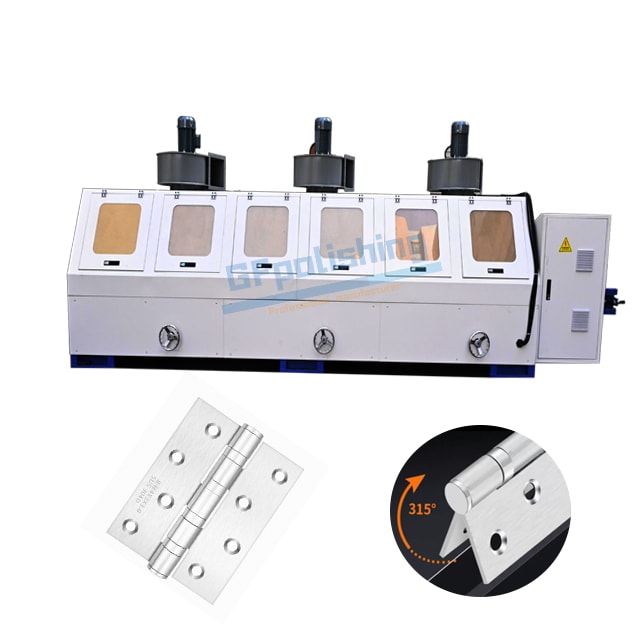

Dongguan guangfan Automation Technology Co., LTD (Guangfan Automation) is a leading hinge polishing machine factory catering to the demands of precision engineering industries worldwide. The company’s comprehensive product line includes automatic hinge polishing machines, hinge grinding machines, hinge surface polishing machines, hinge buffing machines, and more, all designed to deliver exceptional surface finishes and consistent quality for high-performance applications. Guangfan Automation stands out for its commitment to innovation, quality control, and environmental responsibility, integrating advanced automation, energy-efficient designs, and customizable solutions tailored to varied customer needs.

The company’s machines are trusted across a spectrum of fields—including automotive, aerospace, medical devices, electronics, and architectural hardware—thanks to their reliability, flexibility, and industry-leading performance. Guangfan Automation further distinguishes itself through rigorous after-sales support, operator training, upgrade services, and a proactive approach to sustainability. By choosing Guangfan Automation as a hinge polishing machine factory partner, businesses secure a strategic advantage in production efficiency, product quality, and long-term return on investment. In essence, Guangfan Automation provides not just machines, but a holistic partnership for ongoing manufacturing success in the evolving landscape of global precision engineering.

In the demanding world of precision engineering, the role of a hinge polishing machine factory cannot be overstated. Companies worldwide seek advanced solutions to meet high standards in surface finishing, especially in industries where accuracy, consistency, and durability are paramount. Dongguan guangfan Automation Technology Co., LTD, also known as Guangfan Automation, stands out as a premier manufacturer and supplier of hinge polishing machines and related automation equipment. With years of expertise and a reputation built on innovation, Guangfan Automation is the preferred partner for precision engineering firms seeking reliable, high-performance machinery.

The continuous advancement in hinge automatic polishing machines, hinge grinding machines, and hinge buffing machines has enabled companies to achieve new levels of quality and efficiency. This article delves into why selecting a specialized hinge polishing machine factory, like Guangfan Automation, is critical for businesses aiming for superior engineering results, operational efficiency, and sustainable growth.

آلة تلميع صينية أواني الطبخ المصنوعة من الفولاذ المقاوم للصدأ

أواني أواني أدوات المطبخ أواني المطبخ مرآة تلميع المرآة الخارجية

ماكينة تلميع المرايا

آلة صقل وتلميع مقابض الأقفال الكروية للأبواب

ماكينة تشذيب وشطب حافة الطباخ الكهربائي للقطع والشطب

صب غطاء مروحة سقف الألومنيوم الزنك المصبوب من الألومنيوم آلة تلميع وتلميع

Precision engineering is the backbone of modern manufacturing in sectors such as aerospace, automotive, electronics, and medical devices. Components like hinges not only require exact dimensions but also impeccable surface finishes to ensure seamless performance and longevity. A hinge polishing machine factory like Guangfan Automation bridges the gap between raw material processing and final assembly by providing specialized hinge surface polishing machines tailored to specific applications.

Quality hinges and hardware rely on an intricate combination of polishing, grinding, and buffing processes—each requiring top-tier equipment and process know-how. This is where Guangfan Automation’s expertise in manufacturing advanced hinge deburring machines, hinge edge rounding machines, and hinge finishing machines becomes invaluable, ensuring each product meets or exceeds international standards.

Guangfan Automation’s product portfolio integrates the latest technology, including advanced control systems, high-precision spindles, and customizable interface options. This enables customers to select machinery that best fits their unique production requirements, whether for stainless steel hinges, brass hinges, or alloy components.

Achieving a flawless finish is a requirement, not a luxury, in sectors where the visual and tactile quality of hinges influences product reputation. Guangfan Automation’s hinge surface polishing machines utilize innovative abrasive techniques and automated pressure adjustments to deliver mirror-like finishes, consistent across batch after batch.

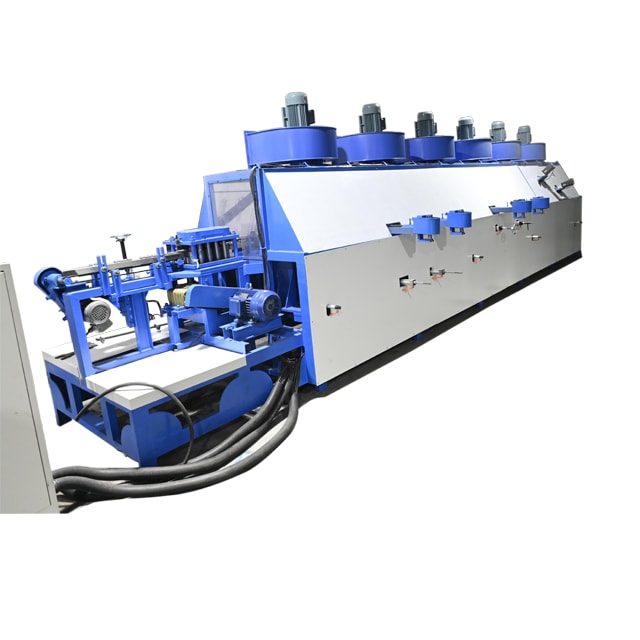

The future of precision engineering lies in the seamless integration of machinery into digital manufacturing systems. Guangfan Automation is at the forefront of this evolution, offering customized hinge polishing machine solutions that integrate with Industry 4.0 protocols, supporting remote monitoring, predictive maintenance, and intelligent data analysis. Such features allow customers to maximize machine uptime and minimize operational costs.

Guangfan Automation invests heavily in research and development to stay ahead of market demands. The company’s dedicated team of engineers constantly refines polishing, grinding, and deburring technologies, resulting in machines that offer higher throughput, enhanced durability, and reduced energy consumption. This relentless pursuit of perfection ensures that each hinge polishing machine reflects the pinnacle of industry innovation.

At every stage of production, Guangfan Automation implements rigorous quality control measures. State-of-the-art inspection systems verify the uniformity of polishing, surface roughness, and dimensional accuracy. Customers can rest assured that every machine delivered from the hinge polishing machine factory meets or exceeds stringent global standards.

Guangfan Automation’s hinge polishing machines serve a diverse range of industries, ensuring adaptability and performance no matter the application. The versatility of their machines in handling varying hinge sizes, materials, and finishing requirements positions Guangfan Automation as an indispensable partner in the supply chain of global precision engineering.

The hallmark of Guangfan Automation’s machinery is its automation capability. Automated hinge polishing machines reduce manual intervention, minimize human error, and enable continuous, high-speed operation. Robotic arms, smart sensors, and adaptive controls ensure each hinge receives uniform treatment, boosting productivity and product quality.

To address sustainability concerns, Guangfan Automation integrates energy-saving features such as variable frequency drives, efficient dust extraction systems, and optimized motor designs. These innovations lower operating costs while contributing to a greener manufacturing environment—and they extend the working life of every hinge polishing machine.

User-friendly human-machine interfaces (HMI) make it easy for operators to program, monitor, and adjust the hinge polishing machines. Real-time diagnostic feedback and remote troubleshooting capabilities further reduce downtime and enhance operational reliability.

No two customers are alike when it comes to hinge finishing requirements. Guangfan Automation distinguishes itself by offering fully customizable hinge polishing machine solutions. From selecting the type of abrasives to designing bespoke workholding fixtures, every aspect of the process can be tailored for maximum efficiency and quality.

With modular machine designs and extensive tooling options, Guangfan Automation ensures that both standard and complex hinge geometries can be processed flawlessly. This flexibility helps customers respond quickly to emerging market trends and customer demands.

For R&D departments and boutique manufacturers, Guangfan Automation offers specialized machines for rapid prototyping and small-batch production. These systems combine the robustness of industrial machines with the adaptability needed for frequent setup changes and experimental processes.

Guangfan Automation’s commitment to customer satisfaction extends well beyond the sale of a hinge polishing machine. Comprehensive after-sales support includes technical training, preventive maintenance programs, and rapid spare parts supply. Expert technicians are available for on-site troubleshooting, remote diagnostics, and process optimization to ensure every hinge polishing machine factory runs at peak efficiency.

Operator training is essential for optimizing machine performance and extending equipment lifespan. Guangfan Automation provides both in-person and remote training modules, empowering staff to safely and effectively manage all aspects of the hinge polishing process.

As technology evolves, Guangfan Automation offers upgrade and retrofit services to enhance existing machines. This ensures factories remain competitive, benefiting from the latest advancements in polishing, automation, and industrial connectivity.

Today’s manufacturers must balance productivity with environmental stewardship. Guangfan Automation addresses this by employing eco-friendly manufacturing practices and designing hinge polishing machines that minimize waste, energy usage, and emissions. Advanced filtration and dust collection systems ensure a clean working environment, while recyclable machine components reduce the company’s overall carbon footprint.

Investing in a high-quality hinge polishing machine from Guangfan Automation delivers measurable long-term value. The combination of advanced automation, reduced manual labor, and high throughput translates into significant cost savings and rapid ROI for precision engineering firms. Lower defect rates and consistent product quality further enhance profitability, giving customers a competitive edge in their respective markets.

In summary, choosing a specialized hinge polishing machine factory like Dongguan guangfan Automation Technology Co., LTD is a strategic investment for any company seeking excellence in precision engineering. The company’s robust portfolio of hinge polishing machines, expert support, tailored solutions, and unwavering focus on innovation make Guangfan Automation the partner of choice for businesses aiming to lead in quality, efficiency, and sustainability.

The evolution of hinge polishing machine technology is shaping the future of global manufacturing. By partnering with Guangfan Automation, precision engineering firms gain access to world-class equipment, industry expertise, and a support network dedicated to their success. As the demands for quality, speed, and sustainability increase, a forward-thinking hinge polishing machine factory becomes not just a supplier, but a strategic collaborator in maintaining competitive advantage and meeting the challenges of tomorrow’s manufacturing landscape.

For companies ready to elevate their production standards and achieve outstanding results, Guangfan Automation offers personalized consultations, product demonstrations, and ongoing partnership opportunities. Connect with their expert team today to discover how the right hinge polishing machine solution can transform your manufacturing capabilities and set new benchmarks for excellence in precision engineering.

من خلال الاستمرار في استخدام الموقع، فإنك توافق على ما يلي سياسة الخصوصية الشروط والأحكام.