A deburring machine is a specialized piece of equipment used to remove burrs, sharp edges, or imperfections from materials after manufacturing processes such as cutting, grinding, or machining. These machines help ensure a smoother finish on metal, plastic, or other materials, which is essential for quality control, safety, and aesthetic purposes.

The price of a metal sheet deburring machine can vary widely depending on the features and specifications. Generally, you can expect prices to range from approximately $5,650 to $50,000. Please 联系我们 if you are looking for direct details on specific models and features.

Metal sheet deburring machines are essential tools used in various industries to improve the quality and safety of manufactured components by eliminating sharp edges and imperfections. Their applications include:

1. Automotive Industry: Deburring machines ensure that parts like chassis and engine components are free from sharp edges, enhancing safety and aesthetic quality while reducing corrosion risk and increasing longevity.

2. Aerospace Industry: In aerospace, where regulatory standards are strict, deburring is crucial to ensure precision and reliability in components such as wings and fuselage sections. Smooth edges from deburring contribute to aircraft safety and performance.

3. Manufacturing: In manufacturing sectors, including machinery and consumer products, deburring machines streamline production, significantly reducing manual finishing needs, enhancing efficiency, and maintaining consistent quality.

4. HVAC Industry: Deburring machines are vital in creating ductwork and components that require smooth edges for proper fit, ensuring optimal performance and minimizing air leaks in ventilation systems.

5. Electronics: The production of metal components for electronic devices benefits from deburring to prevent sharp edges that could lead to electrical shorts or damage.

6. Medical Devices: In the medical field, deburring machines create smooth surfaces on surgical instruments and equipment, reducing the risk of injury or infection.

7. Construction and Structural Engineering: Deburring is vital for construction parts, such as beams and fittings, ensuring proper fit and mitigating safety hazards due to sharp edges.

The versatility of deburring machines allows them to handle various materials and thicknesses, making them suitable for a wide range of applications across different industries. As demand for high-quality, burr-free products increases, the importance of these machines in manufacturing processes remains significant.

When choosing a metal or sheet metal deburring machine, the following factors should be considered:

1. Material Type: Different metals and sheet materials have varying hardness and thickness. Select a deburring machine that is suitable for the specific material being processed.

2. Deburring Process: Determine whether mechanical deburring, chemical deburring, or another method is required. Different processes are suitable for different needs and materials.

3. Production Efficiency: Consider the processing speed and production capacity of the deburring machine to ensure it meets production demands.

4. Precision of the Equipment: The accuracy of the deburring machine directly impacts the quality of the finished product. Assess the uniformity and effectiveness of the deburring.

5. Maintenance and Service: The cost and ease of maintaining the equipment are important factors. Choosing a machine that is easy to maintain can reduce long-term costs.

6. Operational Safety: Select a machine with good safety features to ensure the safety of operators during use.

7. Cost: Consider the purchase cost, operating costs, and maintenance costs of the equipment to ensure overall value for money.

8. Technical Support and After-Sales Service: The quality of the manufacturer’s technical support and after-sales service is crucial, as good service can minimize downtime due to equipment failures.

9. Space and Layout: Assess the machine’s footprint to ensure there is enough space in the production area for normal operation.

By taking these factors into account, you can choose a suitable metal or sheet metal deburring machine that enhances production efficiency and product quality.

The benefits of using metal sheet deburring machines in manufacturing are significant and multifaceted, contributing to enhanced quality, safety, efficiency, and consistency in production processes.

1. Improved Safety

– Removes sharp edges and burrs from metal components, reducing the risk of worker injuries.

– Creates a safer workplace, minimizing the likelihood of accidents.

2. Enhanced Product Quality

– Ensures smooth surfaces on components, meeting aesthetic and functional standards.

– Reduces wear and assembly issues caused by burrs, improving durability.

3. Increased Production Efficiency

– Automated systems significantly shorten production cycles, boosting operational efficiency.

– Machines can operate continuously, reducing manual labor and freeing up resources.

4. Consistency in Quality

– Automated deburring ensures uniform treatment of each part, minimizing quality variations.

– Consistency is vital in industries with stringent compliance requirements.

5. Cost Reduction

– Decreases additional processing or rework costs caused by burrs.

– Saves overall operational costs by improving efficiency and reducing injury risks.

These advantages highlight the importance of metal sheet deburring machines in modern manufacturing, helping businesses optimize processes and ensure high-quality outputs.

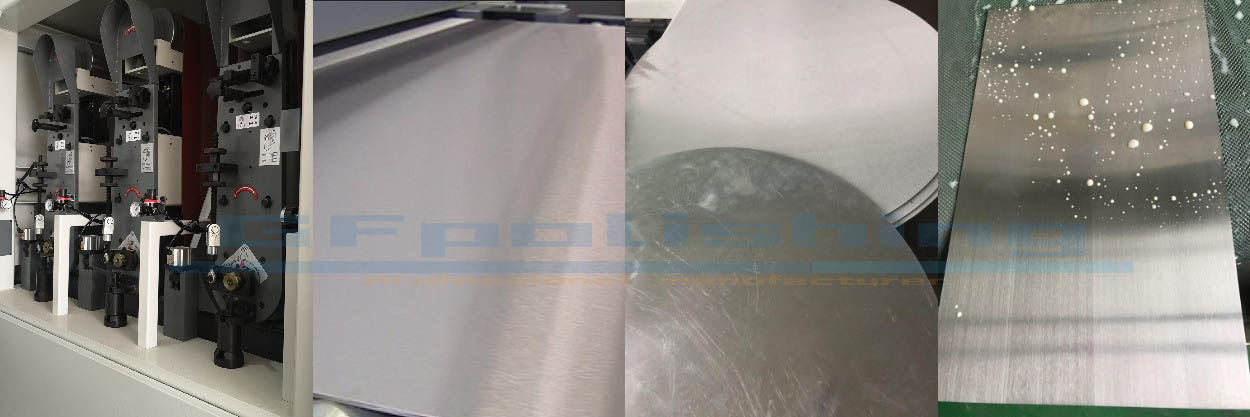

Deburring machines are used to remove excess burrs and sharp edges from the surfaces of metal parts and other materials. They play an important role in various industries, ensuring the safety, aesthetics, and functionality of products. Depending on different processing requirements and material characteristics, there are various types of deburring machines available. meets your needs.

1. Classification by Sheet Width

Based on the different widths of small workpieces and thin sheets, or larger workpieces and metal plates, we provide sheet deburring machines of varying widths to efficiently handle large-scale processing.

2. Classification by Suitable Metals

– Aluminum Deburring Machines: Specifically designed for aluminum materials, these machines usually have lower abrasive characteristics to avoid excessive wear on soft aluminum metals.

– Steel Deburring Machines: These deburring machines are typically built with more durable materials, such as high-hardness steel brushes or belts, to effectively remove burrs from steel surfaces, suitable for heavy industrial applications.

– Stainless Steel Deburring Machines: Often designed to handle corrosion-resistant metals, these machines utilize technologies like waterjet or laser deburring to avoid contact wear and maintain surface quality.

3. Classification by Material Shape

– Sheet Deburring Machines: Often using belt sanders and drum-style deburring machines, these are perfect for large flat surfaces and can efficiently remove burrs and sharp edges.

– Pipe Deburring Machines: These machines are specifically crafted for deburring pipes, utilizing rotary brush or low-pressure waterjet technologies to effectively clean inner surfaces and reach hard-to-access areas.

4. Classification by Technology Type

– Brush Deburring Machines: These machines use rotating brushes to remove small burrs and sharp edges from metal surfaces, making them ideal for irregularly shaped workpieces. They are commonly used in furniture, automotive, and aerospace component finishing.

– Drum Deburring Machines: Employing friction to remove surface burrs, these machines are great for batch processing similar-shaped parts and are widely used in automotive manufacturing and machinery part processing.

– Sanding Machines: This type utilizes the motion of abrasive belts to smooth metal surfaces and is commonly applied to large panels and complex shapes, ensuring high surface quality in woodworking and metalworking fields.

– Laser Deburring Machines: Utilizing high-energy laser beams to precisely remove burrs, these machines are suitable for complex-shaped parts and are ideal for high-precision applications such as medical devices and aerospace components.

– Waterjet Deburring Machines: These machines use high-pressure water to clear surface burrs from workpieces, suitable for a variety of materials, especially advantageous for heat-sensitive materials to avoid thermal deformation.