The metal processing industry is constantly evolving, with manufacturers seeking new ways to improve efficiency, reduce manual labor, and maintain high-quality standards. One area that has seen remarkable technological advancement is surface finishing, particularly with the introduction of automated polishing machines. Dongguan Guangfan Automation Technology Co., LTD, also known as Guangfan Automation, has emerged as an industry leader in providing state-of-the-art solutions such as the Hinge polishing machine and Máy đánh bóng dụng cụ nấu ăn. But how exactly do these machines impact the time and quality of metal processing?

Metal components, whether used in hinges or cookware, require a smooth, polished surface to ensure functionality, safety, and aesthetic appeal. Traditionally, polishing was a manual process, involving significant labor and time investment. Manual polishing not only leads to inconsistencies in finish but also exposes workers to health risks from prolonged exposure to dust and repetitive motion injuries.

As demand for precision and productivity increases, companies like Guangfan Automation have responded by developing automated polishing solutions that streamline the process while maintaining—or even improving—finished product quality.

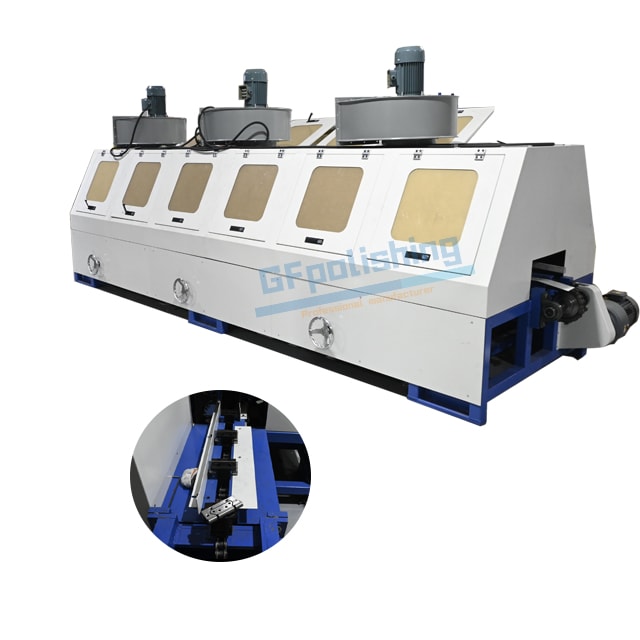

A Hinge polishing machine is specifically designed to automate the surface finishing of metal hinges, which are commonly used in doors, cabinets, and machinery. These machines use a combination of abrasive belts, brushes, and specialized fixtures to ensure every part of the hinge is polished uniformly. Guangfan Automation’s hinge polishing machines are equipped with programmable controls, allowing manufacturers to set parameters for speed, pressure, and polishing duration. This results in a consistent, high-gloss finish with minimal human intervention.

While hinge polishing machines address the needs of the hardware industry, the Máy đánh bóng dụng cụ nấu ăn developed by Guangfan Automation serves the kitchenware sector. Cookware, such as pots and pans, demands a flawless finish for both functional and aesthetic reasons. Automated polishing machines ensure that every piece of cookware receives a uniform polish, enhancing its durability and appearance.

The principles behind cookware polishing machines mirror those of hinge polishers: automation, consistency, and efficiency. These machines can handle various shapes and sizes, adapting to the diverse needs of cookware manufacturers.

The adoption of automated polishing machines is part of a broader trend toward smart manufacturing. According to recent industry reports, the global market for metal surface finishing equipment is expected to grow at a steady pace, driven by the need for higher productivity and stricter quality standards. Companies that invest in automation, such as those using Guangfan Automation’s solutions, are better positioned to meet customer expectations and regulatory requirements.

Moreover, as labor costs rise and skilled workers become harder to find, automation offers a sustainable way to maintain competitiveness. Advanced machines, such as those produced by Guangfan Automation, also integrate with Industry 4.0 technologies, allowing for real-time monitoring, predictive maintenance, and data-driven process optimization.

| Quy trình | Đánh bóng thủ công | Đánh bóng tự động |

|---|---|---|

| Average Time per Hinge | 5-7 minutes | 1-2 minutes |

| Operator Requirement | Skilled worker | Machine operator (minimal training) |

| Sự nhất quán | Varies | Cao |

As shown in the table above, switching from manual to automated hinge polishing can reduce processing time by up to 70%. This not only boosts throughput but also allows manufacturers to allocate human resources to more value-added tasks.

Dongguan Guangfan Automation Technology Co., LTD continues to innovate in the field of metal surface finishing. Their commitment to research and development has led to the creation of machines that cater to a wide range of industries, from hardware to kitchenware. By focusing on automation, Guangfan Automation helps its clients achieve higher productivity, better quality, and enhanced workplace safety.

In addition to Hinge polishing machine and Cookware polishing machine solutions, Guangfan Automation offers comprehensive after-sales support, technical training, and customization options to meet specific client needs. This customer-centric approach has earned the company a reputation for reliability and excellence in the global market.

The answer to whether hinge polishing machines can save time in metal processing is a resounding yes. By automating repetitive and labor-intensive tasks, companies can achieve faster turnaround times, consistent quality, and improved safety. As the metal processing industry continues to embrace automation, pioneers like Guangfan Automation will play a crucial role in shaping the future of manufacturing.

For manufacturers looking to stay ahead in a competitive landscape, investing in advanced solutions such as hinge and cookware polishing machines is not just an option—it’s a strategic imperative.

Bằng cách tiếp tục sử dụng trang web này, bạn đồng ý với các điều khoản của chúng tôi. Chính sách bảo mật Điều khoản và Điều kiện.