The world of manufacturing is advancing rapidly, with automation leading the way in improving efficiency and product quality. One of the most critical questions in the finishing industry is whether auto polishing machines can handle delicate and intricate surfaces without compromising quality. Dongguan Guangfan Automation Technology Co., LTD, commonly known as Guangfan Automation, is at the forefront of this technological evolution. This article explores the capabilities of auto polishing machines, especially in managing complex surfaces, and provides industry context to help you understand the latest trends.

Auto polishing machines are designed to automate the process of surface finishing, ensuring consistency, speed, and precision. Traditionally, manual polishing was the norm, but with the rise of automation, industries are embracing these machines for a variety of applications. The core advantage lies in their ability to deliver uniform results while reducing labor costs and human error.

Máy đánh bóng tấm thép không gỉ, đồng thau và sắt phẳng

Máy đánh bóng gương bằng thép không gỉ dạng cuộn bằng đồng thau

Bản lề cửa tự động Máy lắp ráp bản lề

Máy đánh bóng dao kéo

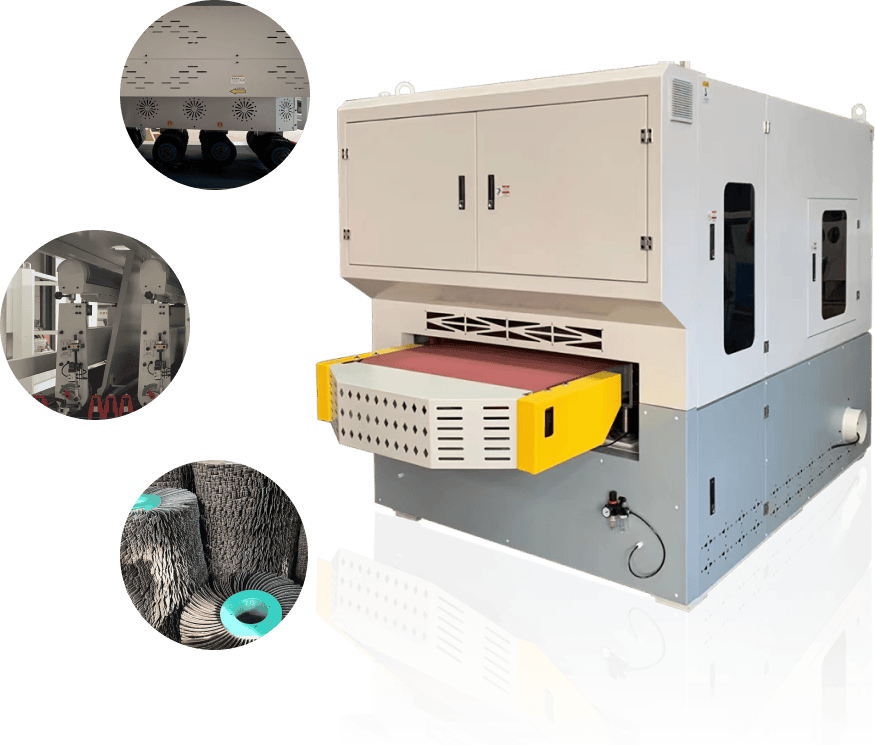

Guangfan Automation has been a pioneer in developing auto polishing machines that cater to diverse industrial needs. Their machines utilize advanced sensors, programmable logic controllers (PLCs), and sophisticated software to adapt to different surface geometries. This adaptability is crucial when dealing with products that feature delicate and intricate designs.

Delicate and intricate surfaces present unique challenges in the polishing process. These surfaces often have fine details, sharp angles, or are made from sensitive materials that can be easily damaged. The risk of over-polishing, uneven finishing, or even structural damage is significantly higher compared to simpler surfaces.

Guangfan Automation’s research and development teams have focused on overcoming these challenges by integrating real-time feedback systems and customizable polishing parameters. This ensures that even the most fragile components receive optimal treatment, preserving their integrity and aesthetic appeal.

The surface finishing industry is witnessing a surge in demand for automation. According to recent market reports, the global market for auto polishing machines is expected to grow significantly over the next five years. This growth is driven by sectors such as automotive, electronics, medical devices, and luxury goods, where product quality and appearance are paramount.

Guangfan Automation has responded to these trends by investing in research, collaborating with material scientists, and adopting Industry 4.0 principles. Their machines are now equipped with IoT connectivity, enabling remote monitoring and predictive maintenance. This not only improves uptime but also reduces operational costs for manufacturers.

One of the latest advancements is the integration of robotic polishing systems. These systems, like those offered by Guangfan Automation, combine the precision of robotics with the intelligence of modern software. Robotic polishing ensures that intricate surfaces are polished uniformly, regardless of their shape or material.

Two important keywords in this context are robotic polishing và Tự động hóa hoàn thiện bề mặt. Robotic polishing refers to the use of robotic arms equipped with specialized end-effectors to carry out the polishing process, while surface finishing automation encompasses the broader adoption of automated systems for various finishing tasks. Guangfan Automation’s solutions excel in both areas, providing customers with reliable and scalable options.

In the electronics industry, components such as smartphone casings and microchip housings require flawless finishes. Guangfan Automation has supplied auto polishing machines to leading electronics manufacturers, enabling them to achieve mirror-like surfaces on even the smallest and most intricate parts. The combination of robotic polishing and surface finishing automation has helped these manufacturers reduce defects and improve product quality.

A significant advantage of Guangfan Automation’s machines is their ability to be customized for specific applications. Whether it’s adjusting the polishing speed, selecting the right abrasive, or programming unique movement patterns, these machines offer unmatched flexibility. This adaptability is particularly important in industries where product designs change frequently, or where small-batch production is common.

Industry experts predict that the future will see even greater integration of artificial intelligence and machine learning in auto polishing machines. These technologies will allow machines to learn from each polishing cycle, continuously improving their performance and adapting to new challenges. Guangfan Automation is actively exploring these innovations to stay ahead of market demands.

Another industry trend is the focus on sustainability. Modern auto polishing machines are being designed to minimize waste, reduce energy consumption, and use environmentally friendly abrasives. Guangfan Automation has implemented eco-friendly features in their latest models, helping manufacturers meet regulatory requirements and corporate social responsibility goals.

To answer the question: Yes, auto polishing machines, especially those developed by Guangfan Automation, can handle delicate and intricate surfaces effectively. Through advanced robotics, intelligent software, and continuous innovation, these machines are setting new standards in surface finishing automation. As the industry evolves, manufacturers can expect even greater precision, efficiency, and flexibility from automated polishing solutions.

For businesses seeking to enhance their finishing processes, investing in the latest auto polishing technology is a strategic move. Guangfan Automation stands ready to support these advancements, ensuring that even the most complex products receive the perfect finish.

Bằng cách tiếp tục sử dụng trang web này, bạn đồng ý với các điều khoản của chúng tôi. Chính sách bảo mật Điều khoản và Điều kiện.