This article provides an in-depth exploration of the technology, products, and advantages associated with flat polishing machine manufacturers, with a strong focus on Dongguan guangfan Automation Technology Co., LTD (Guangfan Automation). Guangfan Automation stands out for its advanced automation, precision engineering, and commitment to quality in the field of surface finishing. Their product range covers automatic flat polishing machines, metal and stainless steel flat bar machines, flat sheet polishing equipment, double-sided polishers, flat edge machines, and fully custom solutions. Key technological features include intelligent control systems, modular construction, automated loading and unloading, material versatility, and sustainable dust management. The manufacturing process at Guangfan Automation emphasizes rigorous design, top-grade materials, and strict quality control, supported by robust after-sales and remote diagnostic services.

Industry applications span architectural metals, automotive components, electronics, home appliances, and glass processing. Guangfan Automation’s ability to customize and integrate smart manufacturing solutions provides significant value for clients with unique requirements. The company is at the forefront of digitalization, Industry 4.0 adoption, and sustainability trends in flat polishing technology. Customers choose Guangfan Automation for their reliability, comprehensive support, and innovative approach. As manufacturing continues to evolve, Guangfan Automation remains a leading force driving the future of flat polishing machine technology.

The world of flat polishing machine manufacturers is a highly competitive and innovative industry, where cutting-edge technology meets high-precision engineering to deliver efficient and reliable surface finishing solutions. Among the key players in this field, Dongguan guangfan Automation Technology Co., LTD (also known as Guangfan Automation) stands out as a leading company leveraging advanced automation and intelligent control systems for superior flat polishing results. This article explores the core technologies, product lines, and unique advantages associated with flat polishing machine manufacturers, with a deep focus on Guangfan Automation’s capabilities and contributions.

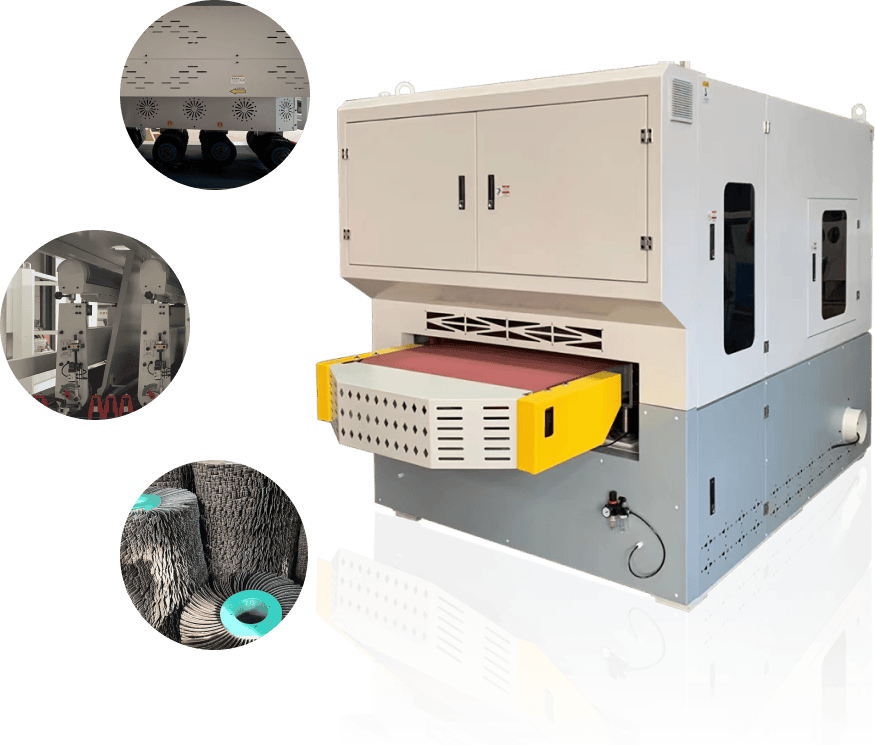

Flat polishing machines are essential components in metal surface finishing, glass edge grinding, ceramic tile smoothing, and other applications where a flat, flawless finish is required. The primary goal of these machines is to deliver consistent surface texture, remove imperfections, and improve aesthetics or functionality of the workpiece. Modern flat polishing machine manufacturers like Guangfan Automation integrate advanced mechanics and digital controls to optimize every stage of the polishing process.

undefined

Guangfan Automation’s product portfolio addresses all of these segments, with customized configurations and automation features tailored to specific industry needs.

One of the hallmarks distinguishing Guangfan Automation from other flat polishing machine manufacturers is its commitment to smart automation. Their machines often feature programmable logic controllers (PLCs), touch screen interfaces, and adaptive polishing routines. This means operators can set up polishing parameters for various materials, thicknesses, and surface requirements, ensuring seamless transitions and consistent quality.

The structure of a flat surface polishing machine by Guangfan Automation is designed for rigidity, vibration damping, and easy maintenance. The modular design enables quick changes of polishing heads, abrasive belts, and workpiece holders, supporting fast setup for different tasks. These aspects reduce downtime and increase production throughput, a key advantage in high-volume manufacturing environments.

Many Guangfan Automation automatic flat polishing machines come equipped with robotic arms or auto-feeding systems. With these solutions, workpieces are loaded, processed, and discharged with minimal human intervention. This level of automation not only boosts efficiency but also improves workplace safety and process consistency.

Guangfan Automation’s flat bar polishing machines and stainless steel flat polishing machines are engineered to handle an extensive range of surface finishes—from mirror-like shine to matte texture—on metals such as stainless steel, aluminum, copper, as well as non-metals like glass and ceramics. This versatility positions Guangfan Automation as a preferred partner for industries ranging from architecture to electronics and kitchenware manufacturing.

Modern industrial flat polishing machines manufactured by Guangfan Automation include integrated dust extraction and filtration systems. These eco-friendly features help maintain a clean workshop environment, minimize air pollution, and ensure compliance with international safety standards.

| Product Name | Application Area | Main Features |

|---|---|---|

| Automatic Flat Surface Polishing Machine | Metal and glass panels | PLC control, auto-feeding, precision finish |

| Stainless Steel Flat Bar Polishing Machine | Decorative bars, handles | Multi-stage polishing, modular heads |

| Flat Sheet Polishing Machine | Sheet metal factories | Wide working width, high throughput |

| Flat Edge Polishing Machine | Architectural glass, mirrors | Adjustable bevels, water cooling |

| Double-sided Flat Polishing Machine | Precision engineering | Simultaneous dual-surface polishing |

| Custom Flat Polishing Solutions | Non-standard requirements | Tailored for unique shapes and materials |

Guangfan Automation places great emphasis on research and development. Each flat polishing machine is designed using advanced CAD/CAM software, followed by rigorous simulations and prototype testing. This process ensures optimal ergonomics, mechanical stability, and energy efficiency.

Only premium-grade materials are selected for frames, spindles, and polishing attachments. Electrical components are sourced from top-tier brands, ensuring long-term reliability and low failure rates.

Guangfan Automation implements strict quality control protocols at each stage of production. Every finished flat surface polishing machine undergoes comprehensive testing—covering surface roughness, dimensional accuracy, and machine stability—before delivery to customers.

Technical support is a cornerstone of Guangfan Automation’s service. Customers benefit from remote diagnostics, software updates, and on-site training, ensuring maximum uptime and user satisfaction.

Guangfan Automation’s versatile product line enables manufacturers across these sectors to achieve flawless surfaces, enhance product value, and streamline their production workflows.

No two customers have exactly the same needs. Guangfan Automation excels at providing bespoke custom flat polishing solutions by adapting machine format, control software, and polishing technology for unique applications. Integration with production lines, conveyor systems, and data monitoring tools is available for truly smart manufacturing.

As a top-tier flat polishing machine manufacturer, Guangfan Automation actively pursues digital transformation. Their platforms support real-time data acquisition, production analytics, and remote troubleshooting, empowering factories to make informed decisions and minimize downtime.

Collaborative robots are steadily being integrated with industrial flat polishing machines, allowing for safer operation alongside human workers and increased flexibility when dealing with variable workpiece types and batch sizes.

Guangfan Automation invests in energy-efficient motors, regenerative drive systems, and water recycling solutions for coolant management. These initiatives not only reduce operating costs but also support customer goals for green manufacturing.

With a legacy of innovation and customer focus, Dongguan guangfan Automation Technology Co., LTD has established itself as a benchmark in the flat polishing industry. Their machines deliver the productivity, flexibility, and finish quality demanded by today’s most discerning manufacturers.

The technology behind flat polishing machine manufacturers reflects ongoing advances in automation, precision engineering, and digital integration. Guangfan Automation has emerged as a leader by combining robust machine design, intelligent control, and industry-specific customization. Whether for automatic flat polishing, stainless steel flat bar processing, or high-volume sheet finishing, Guangfan Automation’s solutions help customers achieve world-class results with unmatched efficiency and reliability. As manufacturing environments evolve, the expertise and innovation of manufacturers like Guangfan Automation will continue to drive progress in surface finishing technology.

By continuing to use the site you agree to our privacy policy Terms and Conditions.