Dongguan Guangfan Automation Technology Co., LTD, abbreviated as Guangfan Automation, has established itself as a trusted name in the automation industry. Specializing in cutting-edge solutions for manufacturing and polishing systems, the company offers high-quality wheel polishing machines that cater to diverse industry needs. To ensure these machines deliver optimal performance and longevity, proper maintenance is crucial.

Wheel polishing machines are vital tools in industries such as automotive manufacturing, aerospace, and metal fabrication. Regular maintenance not only enhances efficiency but also prevents costly downtime. This article provides simple yet effective steps to maintain your wheel polishing machine, ensuring it remains in top condition for years to come.

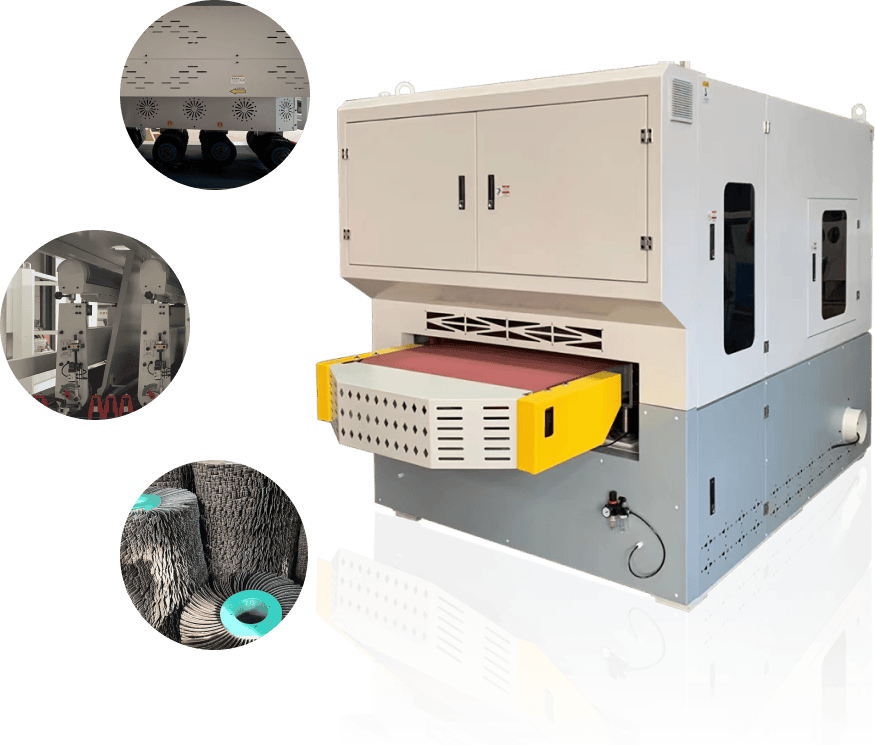

ss scharniere oberfläche kante schleifen poliermaschine

Armaturenroboter Roboter-Polier-, Schleif- und Poliermaschine

poliermaschine für schmuck

1500mm Länge einwellige Flachstangenpoliermaschine

metal polishing buffing machine

Maintaining your wheel polishing machine is essential for several reasons:

Dust, debris, and polishing residue can accumulate on the machine, affecting its performance. Use a soft cloth or brush to clean the machine after every use. Pay special attention to the polishing wheel and other critical components.

Lubrication is essential to reduce friction and wear on moving parts. Apply high-quality industrial-grade lubricants to bearings, gears, and other mechanical components as recommended by Guangfan Automation’s user manual.

Regularly check the electrical connections for signs of wear, loose wires, or corrosion. Faulty connections can lead to operational issues or even pose safety hazards. Replace damaged components promptly.

The polishing wheel is the heart of the machine. Inspect it regularly for signs of wear, cracks, or uneven surfaces. Replace the wheel when necessary to ensure consistent polishing results.

Excessive vibrations can indicate underlying issues such as loose components or imbalanced wheels. Address these problems immediately to prevent further damage to the machine.

Modern wheel polishing machines often include software for automation and precision. Ensure the software is up-to-date and calibrate the machine periodically to maintain accuracy.

Guangfan Automation has been at the forefront of automation technology, offering innovative solutions that cater to the evolving needs of industries. The integration of automation in polishing systems has revolutionized the manufacturing sector, enabling precise finishes and faster production cycles.

One of the key advancements in wheel polishing technology is the use of robotic polishing systems. These systems incorporate robotics to achieve consistent results while reducing manual labor. Guangfan Automation’s machines are designed to leverage automation, ensuring high-quality outcomes with minimal human intervention.

Another trend is the growing demand for environmentally friendly polishing processes. Industries are increasingly adopting eco-friendly practices, such as using water-based polishing compounds and energy-efficient machines. Guangfan Automation remains committed to sustainability by offering machines that align with these practices.

| Maintenance Task | Frequenz |

|---|---|

| Reinigen Sie die Maschine | Täglich |

| Schmieren Sie bewegliche Teile | Wöchentlich |

| Inspect electrical connections | Monatlich |

| Monitor the polishing wheel | Wöchentlich |

| Check for vibrations | Wöchentlich |

| Update software and calibration | Vierteljährlich |

Maintaining your wheel polishing machine is not just a necessity—it’s an investment in its longevity and performance. By following the steps outlined above, you can ensure your equipment remains reliable and efficient for years to come. Dongguan Guangfan Automation Technology Co., LTD takes pride in providing robust and innovative polishing solutions that cater to industry demands.

Whether you’re using robotic polishing systems or exploring eco-friendly processes, Guangfan Automation is your trusted partner in automation technology. Remember, a small effort in maintenance today can save you significant time and costs tomorrow.

Durch die weitere Nutzung der Website erklären Sie sich mit unseren Datenschutzbestimmungen Bedingungen und Konditionen.