Wenn es darum geht, Grate und scharfe Kanten von Metall- oder Kunststoffteilen zu entfernen, ist ein Entgratungsmaschine ist ein unverzichtbares Werkzeug. Bei der Vielzahl der auf dem Markt erhältlichen Optionen kann die Wahl der richtigen Entgratungsmaschine jedoch überwältigend sein. Hier sind einige Schlüsselfaktoren, die bei der Auswahl einer guten Entgratungsmaschine zu berücksichtigen sind:

1. Arten des Entgratens: Bestimmen Sie die spezifischen Entgratungsprozesse, die für Ihre Anwendung benötigt werden. Verschiedene Maschinen sind für unterschiedliche Arten des Entgratens ausgelegt, z. B. für das Entgraten von Kanten, Oberflächen oder Löchern. Vergewissern Sie sich, dass die von Ihnen gewählte Maschine die erforderlichen Entgratungsaufgaben effektiv ausführen kann.

2. Kapazität der Maschine: Berücksichtigen Sie die Größe und das Volumen der Teile, die Sie entgraten müssen. Bestimmen Sie die maximale Größe und das maximale Gewicht der Teile, für die die Maschine geeignet ist. Beurteilen Sie außerdem das Produktionsvolumen, um sicherzustellen, dass die Maschine die erforderliche Arbeitslast effizient bewältigen kann.

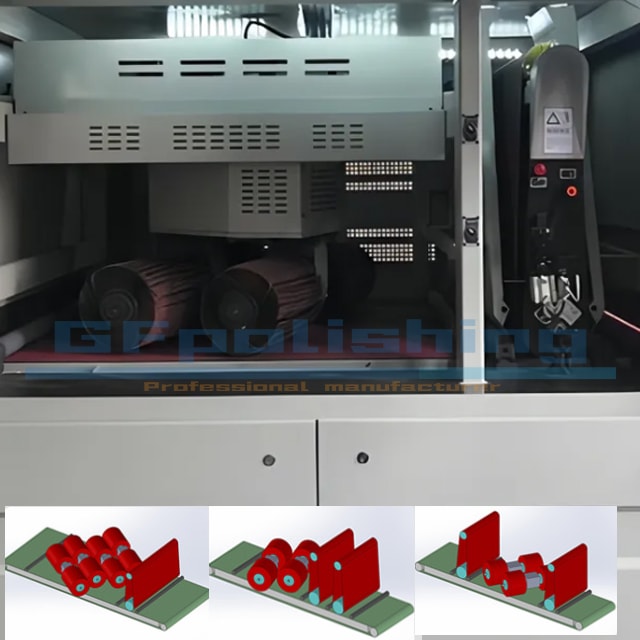

3. Entgratungsmethode: Bewerten Sie die von der Maschine verwendete Entgratungsmethode. Zu den gängigen Methoden gehören das Abrasiventgraten, das Bürstenentgraten, das thermische Entgraten und das Entgraten mit Ultraschall. Jede Methode hat ihre Vorteile und Grenzen. Wählen Sie eine Maschine, die eine für Ihre Anwendung geeignete Entgratungsmethode anwendet.

4. Merkmale der Maschine: Achten Sie auf Merkmale, die die Benutzerfreundlichkeit und Produktivität erhöhen. Dazu können einstellbare Geschwindigkeitsregler, programmierbare Einstellungen, automatische Teilezuführung und effiziente Späneabfuhrsysteme gehören. Berücksichtigen Sie die Flexibilität, Zuverlässigkeit und den Wartungsbedarf der Maschine.

5. Qualität und Langlebigkeit: Vergewissern Sie sich, dass die Entgratungsmaschine aus hochwertigen Materialien und Komponenten hergestellt ist. Suchen Sie nach Maschinen von namhaften Herstellern, die für ihre Zuverlässigkeit und Langlebigkeit bekannt sind. Lesen Sie Kundenrezensionen und holen Sie Empfehlungen ein, um die Leistung und Langlebigkeit der Maschine zu beurteilen.

6. Sicherheitserwägungen: Achten Sie auf Sicherheitsmerkmale und Zertifizierungen. Achten Sie auf Maschinen mit Schutzvorrichtungen, Not-Aus-Schaltern und Einhaltung der einschlägigen Sicherheitsnormen. Stellen Sie die Sicherheit der Bediener in den Vordergrund und stellen Sie sicher, dass die Maschine alle erforderlichen Sicherheitsanforderungen erfüllt.

Wenn Sie diese Faktoren berücksichtigen, können Sie eine gute Entgratungsmaschine auswählen, die Ihren speziellen Anforderungen entspricht, die Produktivität steigert und hochwertige Entgratungsergebnisse liefert. Denken Sie daran, Preise, Garantien und Kundendienst zu vergleichen, um eine fundierte Entscheidung treffen zu können.

Durch die weitere Nutzung der Website erklären Sie sich mit unseren Datenschutzbestimmungen Bedingungen und Konditionen.