In today’s competitive manufacturing landscape, cost-efficiency is a top priority for factories and production facilities. Recent developments from Dongguan guangfan Automation Technology Co., LTD (hereafter referred to as Guangfan Automation) highlight how industrial baghouse dust collectors are emerging as a powerful solution for lowering maintenance costs while improving workplace safety and environmental compliance.

Baghouse dust collectors are filtration systems designed to capture airborne dust and particulate matter generated during industrial processes. Their advanced design not only helps maintain air quality but also significantly reduces the frequency and complexity of equipment maintenance. This article explores how Guangfan Automation’s latest baghouse dust collector technologies are transforming the industry, and how keywords such as “baghouse dust collector” and “industrial dust collector” are shaping the conversation around maintenance cost reductions.

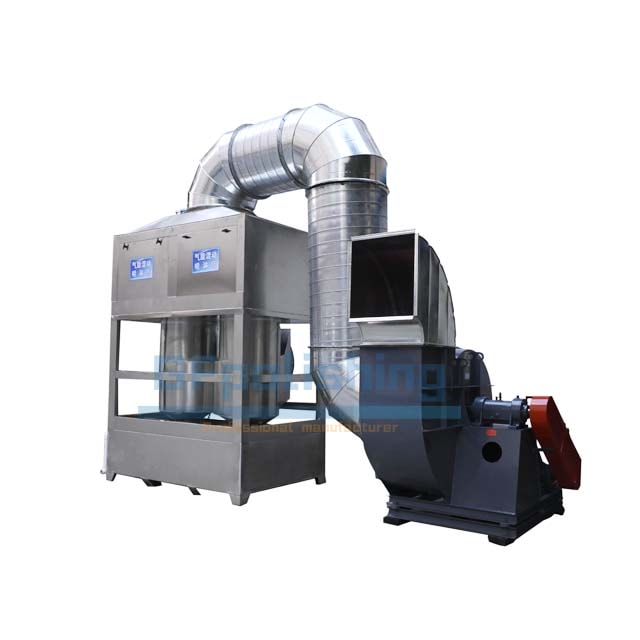

A baghouse dust collector operates by drawing in contaminated air and passing it through a series of fabric filter bags. These bags trap dust particles, allowing clean air to exit the system. Over time, the collected dust is removed from the bags, either manually or automatically, depending on the system’s design. Guangfan Automation has invested heavily in research and development to create baghouse dust collectors that offer superior filtration efficiency and ease of maintenance.

Unlike traditional dust control methods, baghouse systems provide a more comprehensive solution for managing industrial dust. With modular designs, automated cleaning cycles, and durable filter materials, Guangfan Automation’s products help factories reduce downtime and extend the lifespan of their equipment.

Guangfan Automation’s baghouse dust collector solutions are engineered for reliability and minimal maintenance. Their systems are equipped with smart sensors that monitor filter condition and airflow, alerting operators when maintenance is actually needed, rather than on a fixed schedule. This predictive approach ensures maintenance is performed only when necessary, maximizing efficiency and cost savings.

The adoption of industrial dust collector systems has accelerated across sectors such as metalworking, woodworking, cement production, and electronics manufacturing. Factories are increasingly required to comply with stringent environmental regulations, and dust collectors are a vital part of meeting these standards. Guangfan Automation has responded to this demand by offering scalable solutions that can be customized for different industries and facility sizes.

Recent surveys indicate that companies investing in advanced dust collection systems report up to 40% lower maintenance costs compared to those using conventional ventilation or manual cleaning methods. The integration of digital controls and IoT connectivity enables remote monitoring and diagnostics, further reducing the need for on-site inspections and emergency repairs.

| Industry | Maintenance Cost Reduction (%) | Adoption Rate |

|---|---|---|

| Metalworking | 35 | High |

| Woodworking | 40 | Medium |

| Cement Production | 38 | High |

| Electronics | 32 | Medium |

Guangfan Automation’s commitment to innovation is evident in their latest product line, which incorporates energy-efficient motors, modular filter assemblies, and user-friendly control panels. These features not only lower maintenance costs but also contribute to overall operational sustainability.

According to Guangfan Automation’s engineering team, the key to reducing maintenance costs lies in a holistic approach to dust management. “Our baghouse dust collector systems are designed with the end-user in mind,” says a senior engineer at the company. “We focus on durability, ease of access for cleaning and repairs, and smart monitoring technologies to ensure that maintenance is as efficient and cost-effective as possible.”

The company also emphasizes the importance of proper system sizing and installation. A well-designed dust collection system not only lowers maintenance costs but also improves production yields by reducing contamination and equipment downtime.

While maintenance cost reduction is a major benefit, industrial dust collectors offer additional advantages that are driving industry-wide adoption. Improved air quality leads to safer work environments, supporting regulatory compliance and enhancing employee well-being. Efficient dust capture also reduces the risk of fires and explosions in facilities handling combustible materials.

Guangfan Automation is working closely with partners in the automotive, aerospace, and food processing sectors to develop customized dust collection solutions that address unique industry challenges. The company’s focus on sustainability aligns with global trends toward greener manufacturing practices, making their products attractive to environmentally conscious businesses.

The evidence is clear: investing in advanced baghouse dust collectors from Guangfan Automation can significantly lower maintenance costs for industrial facilities. By combining robust engineering, smart automation, and a commitment to customer support, Guangfan Automation is helping manufacturers achieve greater efficiency and compliance in a rapidly evolving industry landscape.

For more information on how Guangfan Automation’s baghouse dust collector and industrial dust collector solutions can benefit your facility, visit their latest product showcase or contact their technical support team for a customized consultation.

Tags:industrial dust collector odm/oem,industrial dust collector company

By continuing to use the site you agree to our privacy policy Terms and Conditions.