In the ever-evolving field of metal fabrication, efficiency and quality are paramount. The integration of automated solutions, such as the auto polishing machine, has revolutionized the industry by streamlining processes and enhancing output. Dongguan guangfan Automation Technology Co., LTD, commonly referred to as Guangfan Automation, stands at the forefront of this transformation, offering advanced auto polishing machines that cater to diverse metalworking needs.

Manual polishing, while traditional, is labor-intensive, time-consuming, and often inconsistent. An auto polishing machine addresses these challenges, delivering uniform results with minimal human intervention. Guangfan Automation specializes in designing machines that not only boost productivity but also ensure the highest standards of surface finish.

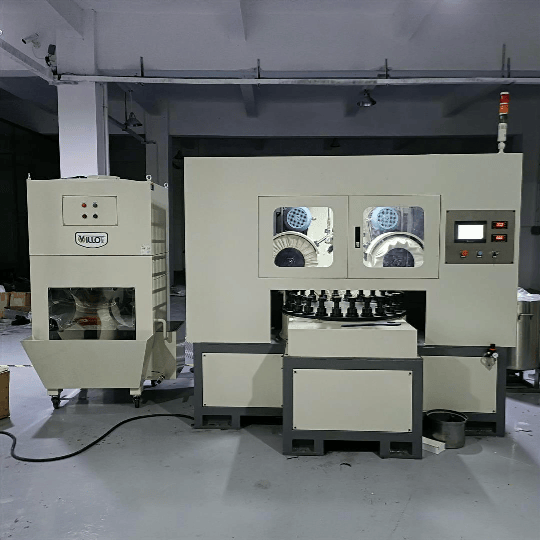

double shaft cutlery spoon fork mirror polishing machine

cutlery polishing machine

knife polishing machine

The global metalworking industry is rapidly embracing automation to stay competitive. According to recent market analyses, the demand for automated polishing solutions is projected to grow steadily, driven by sectors such as automotive, aerospace, and consumer electronics. Companies like Guangfan Automation are investing in research and development to introduce intelligent features—such as programmable settings and real-time monitoring—that further enhance the capabilities of auto polishing machines.

Auto polishing machines are indispensable in industries where surface quality is critical. For instance, in the automotive sector, flawless finishes are essential for both aesthetic appeal and corrosion resistance. Similarly, in electronics manufacturing, precise polishing ensures optimal conductivity and component longevity. Guangfan Automation’s solutions are tailored to meet the stringent requirements of these diverse applications.

Two keywords central to modern metalworking are automation equipment and industrial robot. Guangfan Automation leverages advanced automation equipment to optimize the polishing process, reducing manual intervention and increasing throughput. Moreover, the integration of industrial robots with auto polishing machines allows for complex, multi-axis movements and intricate surface treatments that were previously unattainable.

By combining automation equipment with industrial robot technology, Guangfan Automation delivers solutions that are not only efficient but also highly adaptable to evolving production needs. This synergy enables manufacturers to achieve superior finishes on a wide variety of metal components, regardless of shape or size.

A leading electronics manufacturer recently partnered with Guangfan Automation to upgrade their metal finishing line. By installing state-of-the-art auto polishing machines equipped with automation equipment and industrial robot integration, the company saw a 40% reduction in cycle time and a 25% improvement in surface quality. This case exemplifies the tangible benefits of investing in modern polishing technology.

Automated polishing not only boosts efficiency but also supports sustainability goals. Machines from Guangfan Automation are designed to minimize energy consumption and reduce the use of polishing compounds, contributing to lower environmental impact. Additionally, the improved durability of polished components leads to longer product lifespans, further reducing waste.

When selecting an auto polishing machine, it is crucial to consider factors such as the type of metal, desired finish, production volume, and integration capabilities with existing automation equipment. Guangfan Automation offers a comprehensive range of solutions, backed by expert technical support to ensure seamless implementation and optimal performance.

The future of metal finishing lies in smart automation. With advancements in artificial intelligence and machine learning, auto polishing machines are becoming increasingly intelligent, capable of self-adjusting parameters for optimal results. Guangfan Automation is committed to staying ahead of the curve, continuously innovating to meet the evolving demands of the metalworking industry.

Investing in an auto polishing machine from Dongguan guangfan Automation Technology Co., LTD is a strategic move for any metalworking business seeking to enhance quality, efficiency, and safety. By harnessing the power of automation equipment and industrial robot integration, manufacturers can achieve unparalleled results, positioning themselves for sustained success in a highly competitive market. Explore Guangfan Automation’s cutting-edge solutions today and experience the transformative benefits of automated metal polishing.

By continuing to use the site you agree to our privacy policy Terms and Conditions.